Expectations for Mining Are Changing - And So are The Technologies

|

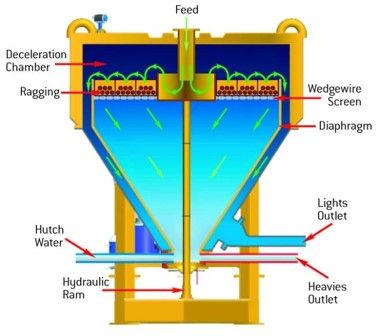

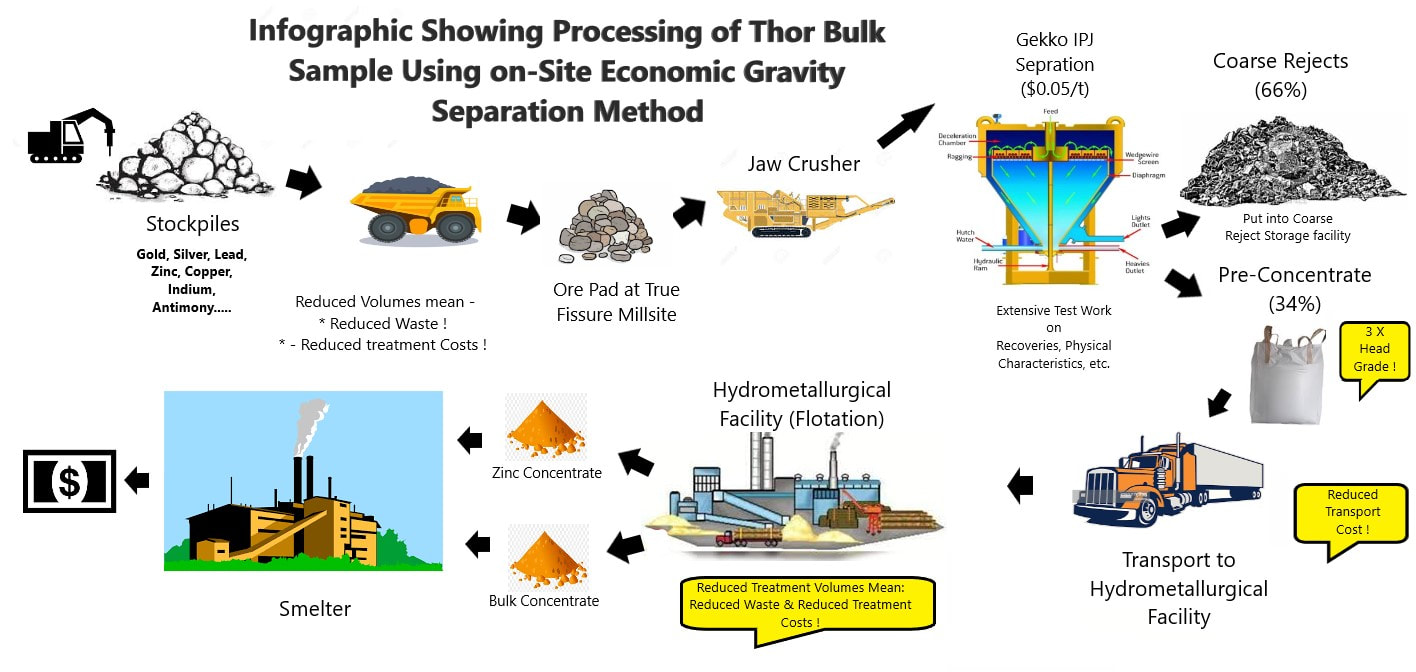

"Gravity concentration is the separation of minerals based on differences in specific gravity. A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses. The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impact. Gekko Systems has repeatedly proven that optimal liberation of mineral at the coarsest particle size reduces energy expenditure across the whole plant. Whether gravity separation of coarse material is used for gangue rejection or pre-concentrating mineral-bearing particles, significant economical and environmental advantages exist"

-Gekko |

The Thor deposit has had three previous periods of mining (early 1900's,early 1930's and early 1970's), and during these periods of mining, ore was stockpiled at several locations on the property where it is readily accessible from surface.

Ore from the Broadview and True Fissure stockpiles is proposed under the existing JEMA to be extracted and processed in a Gekko InLine Pressure Jig ("IPJ") plant where it will be crushed, separated using the IPJ, and bagged for transport and subsequent upgarding. Metallurgical testing by Taranis has shown that virtually all of the minerals of economic value occur in minerals of very high specific gravity. Conversely, waste materials have a much lower specific gravity. The materials will be sorted onsite and pre-concentrate can be shipped offsite for further upgrading, and waste can be separated and dry-stacked on site in coarse reject stockpiles. This process affords the unique ability to upgrade the ore directly onsite using an environmentally friendly mechanical process, and allows the ore-concentrate to be transported much greater distances prior to downstream upgrading and smelting. |